Showroom

Non Woven Bag Printing Machines can be used for printing in multi, single, double, triple and four colors based specifications. These machines are capable of printing maximum 4000 bags per hour.

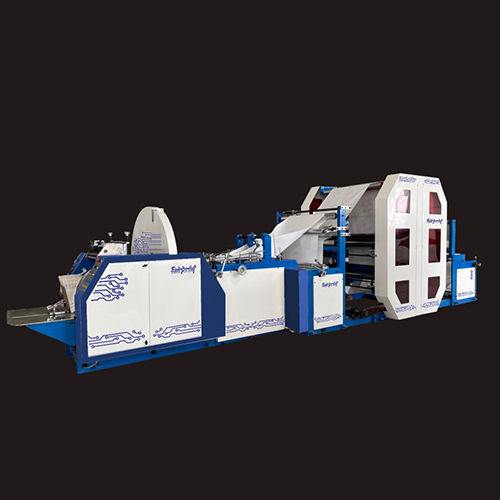

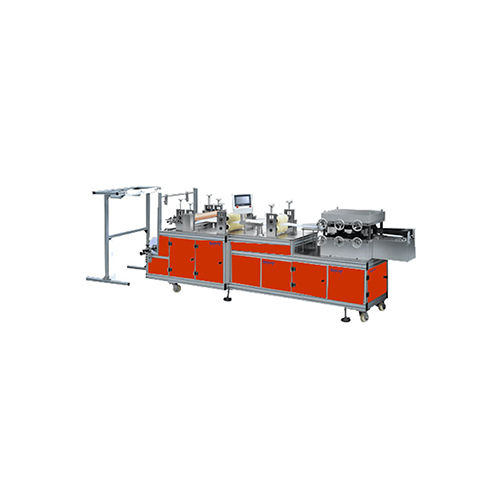

A Non Woven Bag Making Machine is a specialized piece of equipment used to manufacture eco-friendly, durable, and reusable bags from non-woven fabric. These machines are designed for efficient production with automated processes, making them ideal for mass production in the packaging and retail industries. They can produce a wide variety of bag designs, sizes, and styles for different industries.

The Accessories Of Paper Bag Making Machine are additional components or tools that enhance the machine's functionality, improve efficiency, or support specialized production requirements. This expands the machine's capabilities to produce different types of bags. It allows for the creation of custom designs and specialized bags and optimizes material usage and minimize wastage.

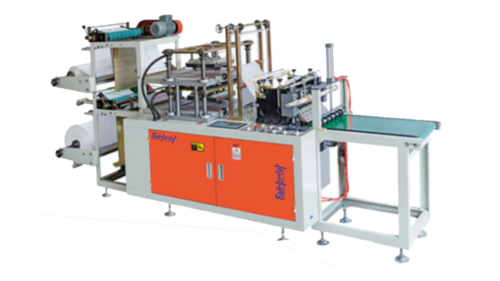

V Bottom Paper Bag Making Machine is highly efficient, producing paper bags in large quantities with consistent quality and speed. It is ideal for carrying lightweight goods in various industries and designed to handle small to medium loads effectively. We ensure these machines are designed to handle continuous operation in industrial settings.

PLC controlled Poly Printing Machines can print PE bag in single and double colors. These automatic equipments comprise of motor frequency controller, web guide, auto tension controller, rubber roller and anilox roller.

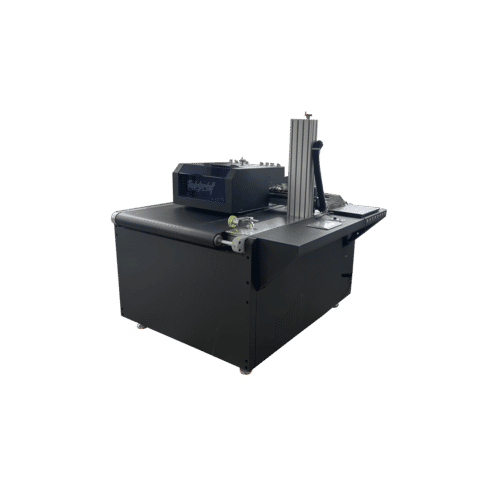

We offer Variable Data Printing Machines, which are utilized for heavy duty frame structures. These come with well-tried advanced speed stream intake technology and offer vibration free operation. These machines are featured with printing conveyors, double sheet detection and heavy duty pile lift system. The PLC based control panels and automatic speed controls of these products ensure the operational efficiency.

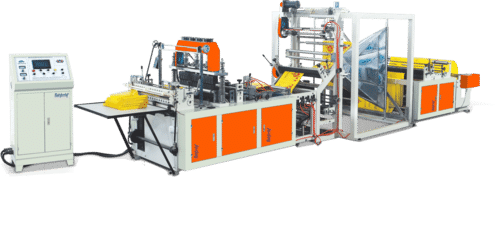

Non-Woven Bag Making Machines are offered with controlled and meticulous performance. These have integrated with various control devices like auto-counting and different other safety alarms for a harmless and secured operation. Also incorporated with advanced ultrasonic-bonding technology, these ensure extremely strong seal in the bags. Assisting in making non-woven bags, these are also featured with auto tension control as well as high speed cutting.

PLC controlled Paper Bag Making Machines use 220v power and maximum 80 gsm paper to produce bags of desired features. These automatic machines are capable of executing color marking and force controlling steps without any error.

A Sheet Fed Offset is a type of offset printing technology where individual sheets of paper, cardstock, or other materials are fed into the machine for printing, as opposed to continuous rolls of material used in web offset printing. This is suitable for everything from business cards to large posters. It provides vibrant colors, sharp images, and high detail, making it ideal for premium products.

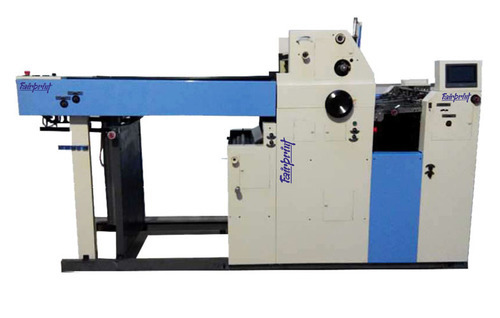

A Mini Offset is a compact, smaller version of a traditional offset printing machine. These machines are ideal for small-scale printing jobs and are widely used for printing stationery, business forms, brochures, envelopes, and small advertising materials. Rugged construction ensures longevity and reliability. Its versatility, compact size, and affordability make it an excellent choice for startups, small printing firms, and in-house corporate printing departments.

This range of Handle Loop Making Machines adopts advanced heat sealing technology. These equipments are suitable for high temperature prone working environment. Flexible parameters of their feeding section helps to maintain precision of loop handle.

A Square Bottom Paper Bag Making Machine is a specialized machine designed for producing paper bags with a flat, square-shaped bottom. The machine automates the process of creating strong, eco-friendly bags that meet the growing demand for sustainable alternatives to plastic bags. With its automated operation, versatility, and ability to produce durable bags, it caters to industries seeking sustainable alternatives to plastic.

All In One Making Machine is a versatile piece of equipment designed to perform multiple tasks or processes in a single unit, often streamlining production, reducing costs, and saving space. These machines are particularly beneficial for businesses with diverse requirements or limited resources. They are built with industrial-grade components to handle extended use in demanding environments.

A Single Pass Digital Printer is an advanced digital printing system which is demand for high-speed, precise, and efficient printing. It is ideal for large-scale production with faster turnaround times. Its efficiency and versatility make it invaluable for packaging, textiles, ceramics, and commercial printing. These printers, reduces waste by eliminating the need for printing plates or screens.